Dust collecting systems are designed to improve air quality within industrial settings. These machines consist of several components, all of which work together to reduce atmospheric workplace contamination caused by dust particles. They are commonly found in locations such as manufacturing facilities, workshops, and plants. Read More…

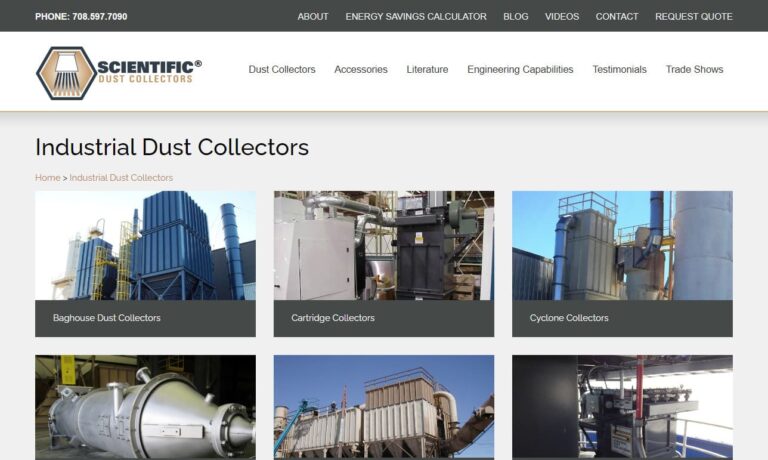

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

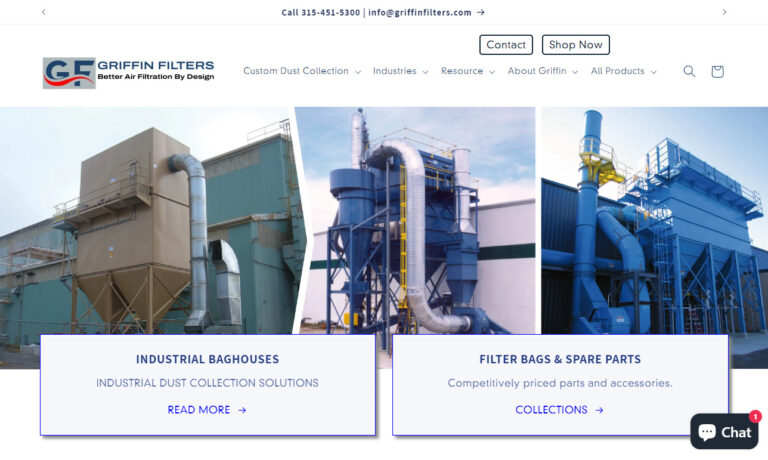

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

Here at Camfil APC, we understand that during the manufacturing process dust and other pollutants are introduced to the air. In order to combat this we have a wide variety of dust collecting systems that include, but are not limited to, our Gold Series® Industrial Dust Collector, Quad Pulse Package, and our Zephyr III®. We service the food & beverage, chemical processing, pharmaceutical,...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Dust Collecting System Manufacturers

Dust collecting systems are designed to improve air quality within industrial settings. These machines consist of several components, all of which work together to reduce atmospheric workplace contamination caused by dust particles. They are commonly found in locations such as manufacturing facilities, workshops, and plants

Why Use Dust Collecting Systems?

Although it is usually vague, the term dust can be defined as any miniscule, solid, and airborne particle produced by some process of physical disintegration. Most fabrication industries depend on processes that release dust particles into the air and pose a threat to the well-being of industrial equipment and the workers who manage them. A sampling of respiratory health issues associated with dust contamination include bronchitis, severe asthma, and cancer. (Some of these and similar issues are caused by fine chemicals or fungi embedded within industrial dust.) Dust contamination also threatens the industrial workplace by increasing its susceptibility to fire or spontaneous explosions.

Dust collecting systems are built to help minimize the threats posed by dust contamination as much as possible. Some disadvantages of these systems are the fact that they take up a lot of space and, once designed, cannot be easily reconfigured. Industrial businesses, however, generally find dust collecting systems necessary to comply with governmental standards for regulating emissions. While the elaborate design and installation of dust collecting systems may prove inconvenient at times, these systems generally “pay off” in the long run by enabling more effective particle reduction in the air, increasing longevity of equipment and improving working conditions for employees.

How Dust Collection Systems Work

Dust collection systems for cleaning air generally follow three key steps: capturing contaminated air, transporting it to a central collection unit through pressure, and filtering out harmful substances before expelling clean air.

Despite variations, most dust collection systems share core components. Suction hoods (also known as exhaust hoods, capture hoods, or capture arms) are positioned over or attached to dust-producing areas, such as a machine’s dust port, to capture dust at the source. Ducts act as passageways, transporting the captured contaminated air to the central suction unit, which is powered by a fan or motor that creates airflow through the capture points. The system’s “heart” consists of filters or dust collectors, which may be standalone or arranged in series, responsible for removing harmful particles from the air.

Dust collection systems are adaptable to various needs and conditions. Some systems release purified air back into the workspace, enhancing the overall air quality, while others are designed to recover valuable dust particles from an industrial process.

Types of Dust Collection Systems

Dust collection systems are fundamentally defined by their filtration components, which are the core of their operation. These filters come in various shapes, designs, and materials, such as synthetic cellulose, polyester-silicon complexes, and different types of cloth.

These systems often use multiple types of collectors. Below is an overview of some common and notable types:

Baghouses are the most prevalent and efficient dust collectors. They use a fan to create a vacuum that pulls contaminated air through fabric filters housed in bags. The filters capture dust particles, allowing clean air to exit while the dust settles in the bottom of the chamber. Baghouse types differ in their methods for cleaning filter bags:

- Shaker collectors shake the bags at intervals to remove dust.

- Reverse air collectors temporarily reverse airflow to reduce dust buildup.

- Jet collectors use air jets to clean the filters.

Cyclone dust collectors (or cyclone separators) are inertial separators that use centrifugal force to separate dust from air within a hopper-shaped chamber. A rotating gas stream creates centrifugal force, forcing particles against the chamber wall, where they eventually settle. Variants include skimmer cyclones, reverse-flow cyclones, axial flow cyclones, and secondary air flow dust collectors. Cyclones are typically used for initial dust removal in industrial operations.

Dust Extraction Systems are crucial for production facilities, workshops, factories, and industrial complexes. They filter particulate contaminants from the air, helping to maintain a clean and safe environment. Industries such as mining, asphalt production, chemical processing, welding, pharmaceuticals, and food processing benefit from these systems. They also act as fire suppression systems by collecting flammable and explosive dust, reducing odors, and ensuring compliance with safety and environmental regulations. Proper dust collection enhances production quality, worker morale, and efficiency. Therefore, understanding the types, components, and materials of dust collection systems is essential for business owners and engineers, especially as environmental concerns grow.

Baffle Chamber Dust Collectors operate similarly to cyclones but use rapid redirection instead of rotational force. They employ stationary baffle plates to redirect contaminated air, causing large dust particles to settle in a “dead space” for collection.

Wet Scrubbers clean air by forcing it through a scrubbing liquid, usually water. The effectiveness of the scrubber depends on how well the air contacts the liquid. Water droplets capture dust particles through inertia or diffusion, and after passing through the scrubber, the air is dehumidified by mist eliminators. Solids collect at the bottom for removal. Wet scrubbers include:

- Wetted Surface Scrubbers (e.g., baffle spray scrubbers, cyclonic spray scrubbers, fibrous bed scrubbers)

- Distributed Liquid Scrubbers (e.g., spray tower scrubbers, plate tower scrubbers, self-induced spray scrubbers)

Electrostatic Precipitators (ESPs) use charged ions to clean air. Ions attract dust particles, which are then deposited on a collection electrode. ESPs can be single-stage or double-stage, depending on whether the charging and collection occur in the same area. They can have plate or tubular configurations and use methods like rapping, liquid film, or liquid spray to remove collected dust.

Central Dust Collection Systems are installed in a fixed location and connect to dust sources via ducts. Alternatively, portable collectors offer localized dust collection, moving between machines for convenience. Examples include shop vacuums for handheld tools and downdraft tables for independent work areas.

Dust Collection System Accessories

Dust collection system accessories are essential for boosting the effectiveness and efficiency of these systems, which are vital for maintaining clean and safe work environments across various industries. These accessories enhance the primary dust collector’s performance. For example, high-quality filters, like HEPA filters, trap finer particles, improving air quality and preventing harmful dust from re-entering the workspace. Dust separators or cyclones are crucial for pre-separating larger debris before it reaches the main dust collector, which reduces the system’s load and increases efficiency. Blast gates help control airflow, directing suction to specific machines or work areas, thus optimizing both collection efficiency and energy use.

Beyond improving air quality and performance, dust collection accessories also contribute to worker safety and health. By reducing airborne dust, they lessen the risk of respiratory issues and other health problems associated with prolonged exposure to harmful particles. This is particularly important in industries such as woodworking, metalworking, and construction, where dust and debris are prevalent. Additionally, many industries face strict regulations regarding air quality and dust emissions. Using the right accessories helps companies comply with these regulations, avoiding potential fines or legal issues.

Moreover, dust collection accessories extend the lifespan of the main dust collector and reduce maintenance needs. By pre-separating larger debris and filtering finer particles, these accessories prevent excessive wear and tear on the dust collector’s components, thereby extending its operational life. Efficiently maintained systems also require less frequent upkeep, saving time and money.

To acquire the necessary accessories, individuals and businesses have several options. They can visit home improvement stores, specialty woodworking shops, or explore online retailers that offer a broad range of accessories. Manufacturers often sell accessories directly on their websites or through authorized dealers, providing high-quality, compatible options for their specific dust collection systems. For specialized industrial applications, industrial equipment suppliers are reliable sources. Additionally, for cost savings, some accessories, such as collection bags, can be purchased second-hand in good condition.

In summary, dust collection system accessories play a crucial role in enhancing collection efficiency, improving air quality, ensuring safety and regulatory compliance, and extending the life of the main dust collector. These accessories are vital for maintaining a clean and safe work environment, promoting worker health, and optimizing dust collection system performance. Understanding the available options and sourcing them effectively helps individuals and industries achieve the best results.

Industries That Use Dust Collecting Systems

Dust collection systems are essential across a wide range of industries, playing a key role in maintaining a safe and productive work environment. In sectors like cement production, mining, metal fabrication, steel mills, and scrap metal operations, these systems are crucial for controlling dust and airborne particles that arise during material processing and shaping. Metalworking and woodworking shops also benefit from dust collection systems, which capture debris from cutting, grinding, and shaping processes, thereby ensuring cleaner air and mitigating combustible dust hazards. Recycling facilities use these systems to manage dust generated during the sorting and processing of recyclable materials, enhancing worker safety and keeping the environment clean.

In the pulp and paper industry, dust collection systems are vital for capturing wood fibers and fine particles created during manufacturing, preventing them from becoming airborne and posing health risks to employees. Sawmills similarly use these systems to manage wood dust and chips from lumber processing, reducing health hazards and fire risks. The automotive and glass industries depend on dust collection systems to control dust and fumes produced during cutting, grinding, and shaping, protecting worker health and ensuring high product quality.

In construction, dust collection systems are crucial for handling dust and debris from activities like cutting, drilling, and sanding, leading to a safer and cleaner work environment. Additionally, the medical and pharmaceutical industries rely on these systems to manage dust and particulate matter generated during the production of medications and medical products, maintaining stringent cleanliness and safety standards.

Overall, dust collection systems are indispensable across various sectors, including cement fabrication, metal fabrication, mining, woodworking, recycling, agriculture, automotive, construction, medical, pharmaceutical, glass, and more. They play a significant role in enhancing worker safety, air quality, and overall productivity by effectively capturing and containing airborne dust and particles from industrial processes, making them a vital investment for any facility where dust is a concern.

Care and Upkeep

Proper care and maintenance of dust collection systems are essential for their optimal performance and longevity. The frequency of inspections, cleaning or replacing filters and collection bags, emptying collection bins, and lubrication should be based on several factors. First, adhere to the manufacturer’s guidelines, which generally provide detailed instructions on maintenance schedules, cleaning intervals, lubrication needs, and more. Generally, inspections should be conducted regularly—at least monthly for smaller systems and more frequently for larger or heavily used ones. Filters and collection bags typically require cleaning or replacement every three to six months for standard applications, though more frequent maintenance might be necessary in high-demand environments. Collection bins should be emptied based on dust volume, which could range from daily to monthly. Lubrication should follow the manufacturer’s recommendations, usually every few months to annually. Following these guidelines helps ensure efficient operation, promotes a safe work environment, and extends the system’s lifespan. If any performance issues arise, increase the frequency of inspections and maintenance or seek professional help as needed.

Considerations When Choosing a Dust Collector

It’s essential to recognize that a dust collection system performs best when integrated into a broader air quality control strategy, which often includes various other components. Dust collection systems are complex and highly customizable, so selecting a supplier with a reputation for expertise, quality products, and excellent customer support is crucial.

When choosing a dust collection system, several factors come into play. The type of dust you’re dealing with determines the appropriate dust collector and filtration media. For instance, synthetic cellulose filters are effective for dry dust, whereas “spun-bond” filters handle moist or sticky dust better.

The system’s capacity to remove dust and its speed of operation are also critical. A dust collector needs to move large volumes of air quickly. Air velocity is measured in feet per minute (fpm), and air volume in cubic feet per minute (cfm). Different dust sources have specific cfm requirements for effective dust removal. For example, high-powered woodworking tools often require systems with a 1000-cfm capacity. Additionally, factors like duct size and static pressure, which refers to the friction within the ductwork, influence the system’s effectiveness. Accurate calculations of these requirements, potentially with help from a manufacturer or supplier, are vital before investing.

Choosing between a central or portable dust collection system depends on your needs. Central systems are best for environments that require significant vacuum power and where space conservation is important. They can be placed farther from dust sources due to their higher capacity and are suited for permanent setups in large industrial settings. Portable systems are more affordable and simpler but are better suited for situations where power requirements are less critical.

Finally, even the best dust collection systems cannot achieve 100% efficiency, so it’s worth considering a secondary auxiliary system if necessary. Recirculating air back into the environment can offer significant benefits. It can help meet governmental emission regulations, which can be costly and cumbersome, and it can also provide additional financial savings by conditioning the air as it cleans it.

Dust Collector-Quality Air Management

Dust Collector-Quality Air Management

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services