For a job like this, the solution is a dust collector. Dust collectors enhance air quality by separating dust and other impurities from air or gas. There are four main types of dust collectors. One of these is the wet dust collector, also called the wet dust scrubber. Read More…

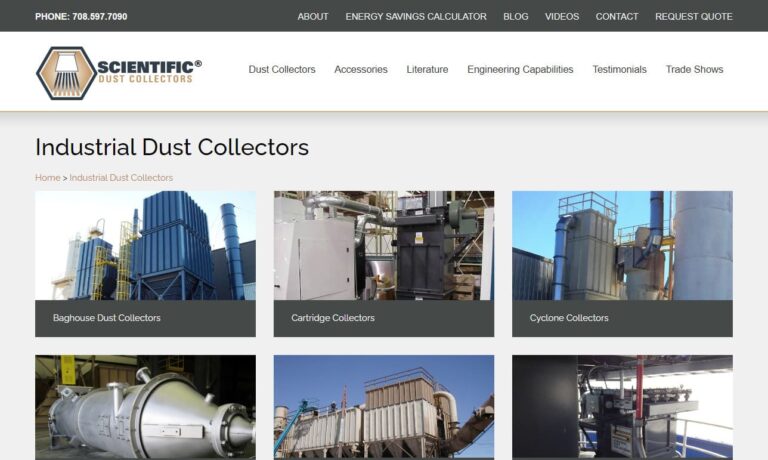

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

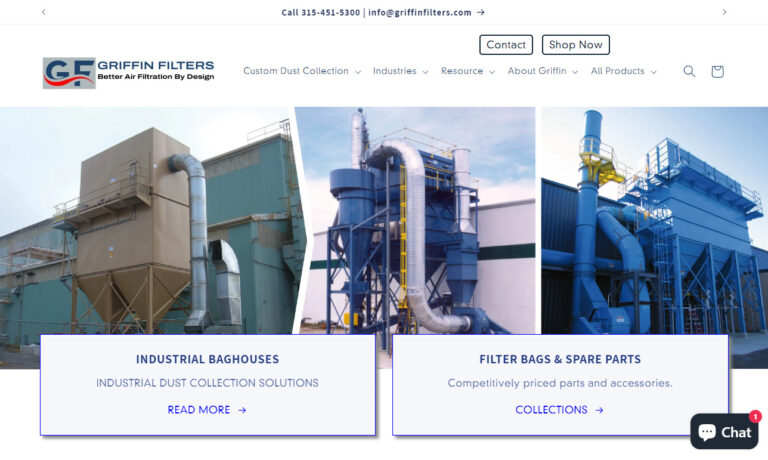

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

Here at Camfil APC, we understand that during the manufacturing process dust and other pollutants are introduced to the air. In order to combat this we have a wide variety of dust collecting systems that include, but are not limited to, our Gold Series® Industrial Dust Collector, Quad Pulse Package, and our Zephyr III®. We service the food & beverage, chemical processing, pharmaceutical,...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Wet Dust Collector Manufacturers

Wet dust collectors use some sort of liquid, most commonly water, to separate and absorb dust and other fine particulates. All varieties of wet dust collectors have one of three basic configurations: gas-humidification, gas-liquid contact (inertial impaction, interception, diffusion or condensation nucleation) or gas-liquid separation. After dust collection, the "cleaned" or "scrubbed" gases are normally passed through a demister to remove the added water droplets. Afterwards, the dirty water is either cleaned and discharged or recycled to the dust collector.

Dust is removed using a clarification unit or drag tank chain, the latter of which will remove the sludge and deposit it in a dumpster or stockpile. There exist multiple types of wet dust collectors, categorized by pressure drop.

They are as follows: low-energy collectors (0.5 to 2.5 inches water gauge and 124.4 to 621.9 Pa), low-to-medium energy collectors (2.5 to 6 inches water gauge and 0.622 to 1.493 kPa), medium-to-high energy collectors (6 to 15 inches water gauge and 1.493 to 3.731 kPa) and high-energy collectors (greater than 15 inches water gauge and greater than 3.731 kPa).

One type of low-energy wet dust collector is the gravity-spray-power scrubber. This scrubber collects atomized liquid droplets that form in its spray nozzles, which then fall through rising exhaust gases. Dirty water is drained at the bottom.

Gravity-spray-power scrubbers are approximately 70% efficient on 10 µm particles, and work poorly under this threshold. They do, however, treat relatively high dust concentrations without clogging. An example of the low-to-medium energy wet dust collector is the wet cyclone, which uses centrifugal force to spin dust particles, throwing them onto its wetted wall, where the dust is then washed away by water introduced from the top.

These collectors operate efficiently for 5 µm particles and above. Markets for wet dust collectors include woodworking, food processing, foundry, material handling, building restoration, plastics and resins, and much more.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services