Particles are released from material processing in nearly every fabrication industry, from large wood shaving particles or metal shaving particles to fine, respirable chemicals and smoke particles. Read More…

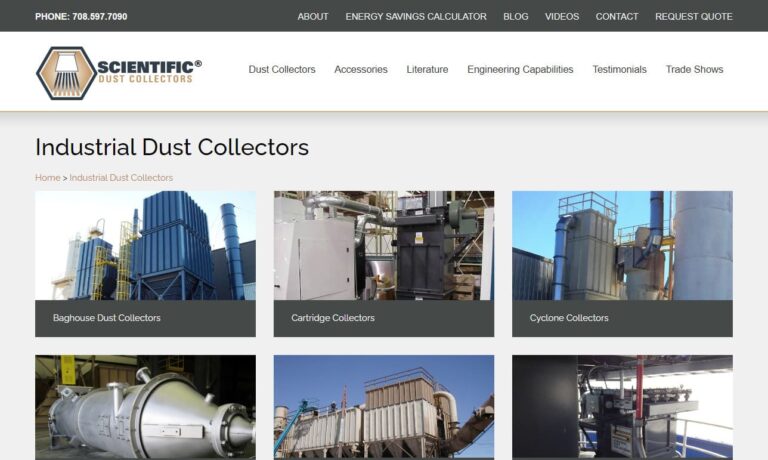

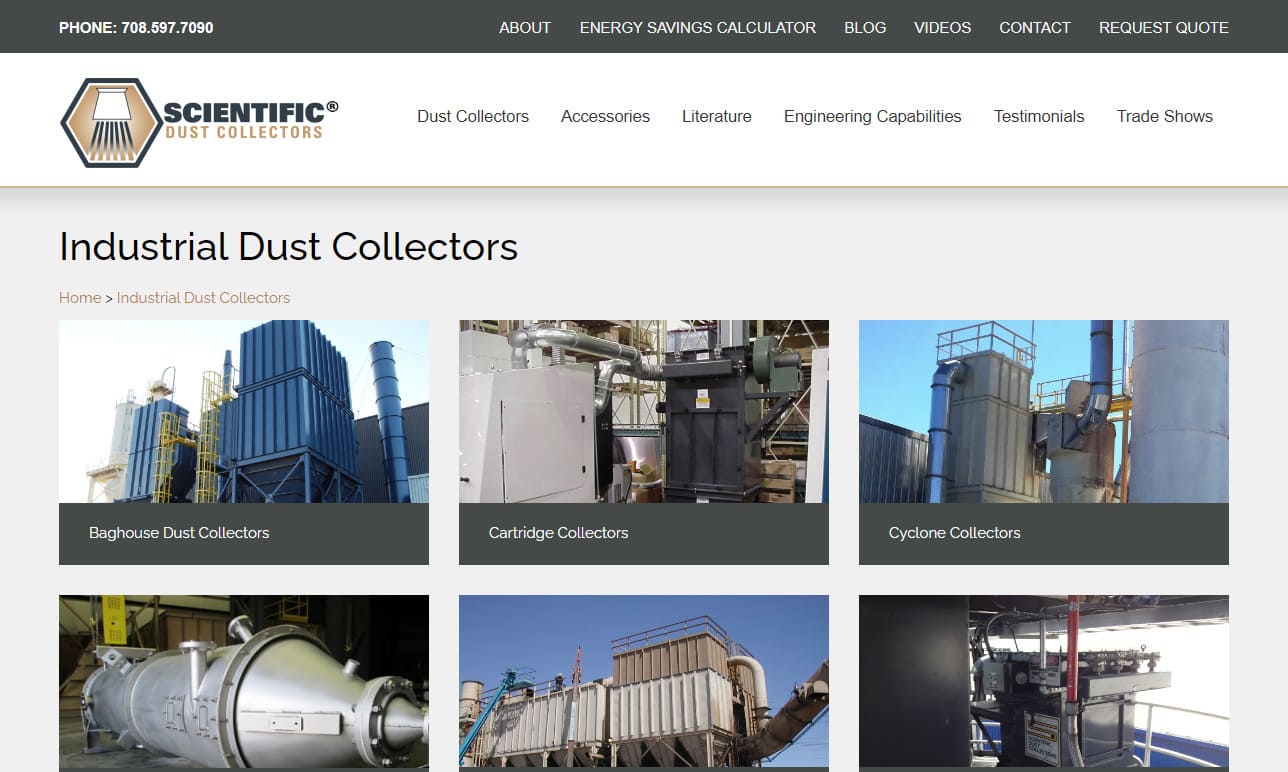

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

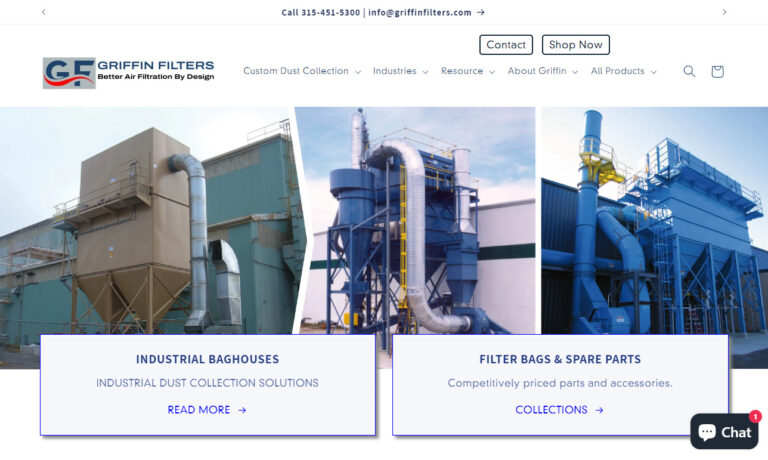

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

Here at Camfil APC, we understand that during the manufacturing process dust and other pollutants are introduced to the air. In order to combat this we have a wide variety of dust collecting systems that include, but are not limited to, our Gold Series® Industrial Dust Collector, Quad Pulse Package, and our Zephyr III®. We service the food & beverage, chemical processing, pharmaceutical,...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Dust Collection Manufacturers

Air particles released during manufacturing processes are hazardous to both worker and equipment health, quickly leading to a number of problems if particles are not removed from facility air.

Dust collection addresses this problem of air contamination by drawing contaminated air into a collection apparatus, trapping harmful particles and releasing cleaner air into the atmosphere or back onto the work floor.

Applications requiring dust collection include sanding, sawing, or grinding almost anything, metalworking, toxic media, product recovery, scrap metal recycling, chemical processing and steel sintering.

Dust collection is a vital process for coal handling, cement fabrication, metal fabrication, mining, chemical processing, woodworking, recycling and agricultural industries, among many others.

State OSHA regulations require industries with smoke-, dust-, or particle-emitting processes to comply with clean air standards for their workplaces, and environmental regulations limit acceptable outdoor emissions. As the dust collection industry advances, smaller and more efficient filtering equipment is being developed to meet increasingly strict occupational safety and environmental regulations.

Different types of dust collectors can be used in dust collection systems including bag houses, cyclone dust collectors,jet dust collectors, and portable dust collectors.

Baghouses, the most common dust collector design, draw dirty air in through ducts to a hopper-shaped baghouse containing fabric filters bags. A large blower creates a vacuum that draws the air from the facility into the collection chamber and then through the fabric bags, leaving behind the dust, smoke and particles; the clean air exits through the fan at the outlet, while dust particles settle into an airlock at the bottom of the hopper.

Similarly, jet dust collectors are a type of baghouse that use jets of reversed air to shake the dust-caked fabric bag filters free of dirt.

Cyclone dust collectors are inertial separators which use centrifugal air movement within a hopper-shaped chamber to separate particles from the air; the heavier particles hit the outer wall of the hopper and gravity brings them down to the bottom of the hopper, where they are collected.

Portable dust collectors, which generally use fabric or cartridge filters, can be moved around to various workstations for localized dust collection.

Wet dust collectors are special dust collection devices that can capture both solid particulate and gaseous impurities in the air using chemical reactions and absorption techniques, and are often used to collect flammable metal dusts like magnesium, aluminum or titanium.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services